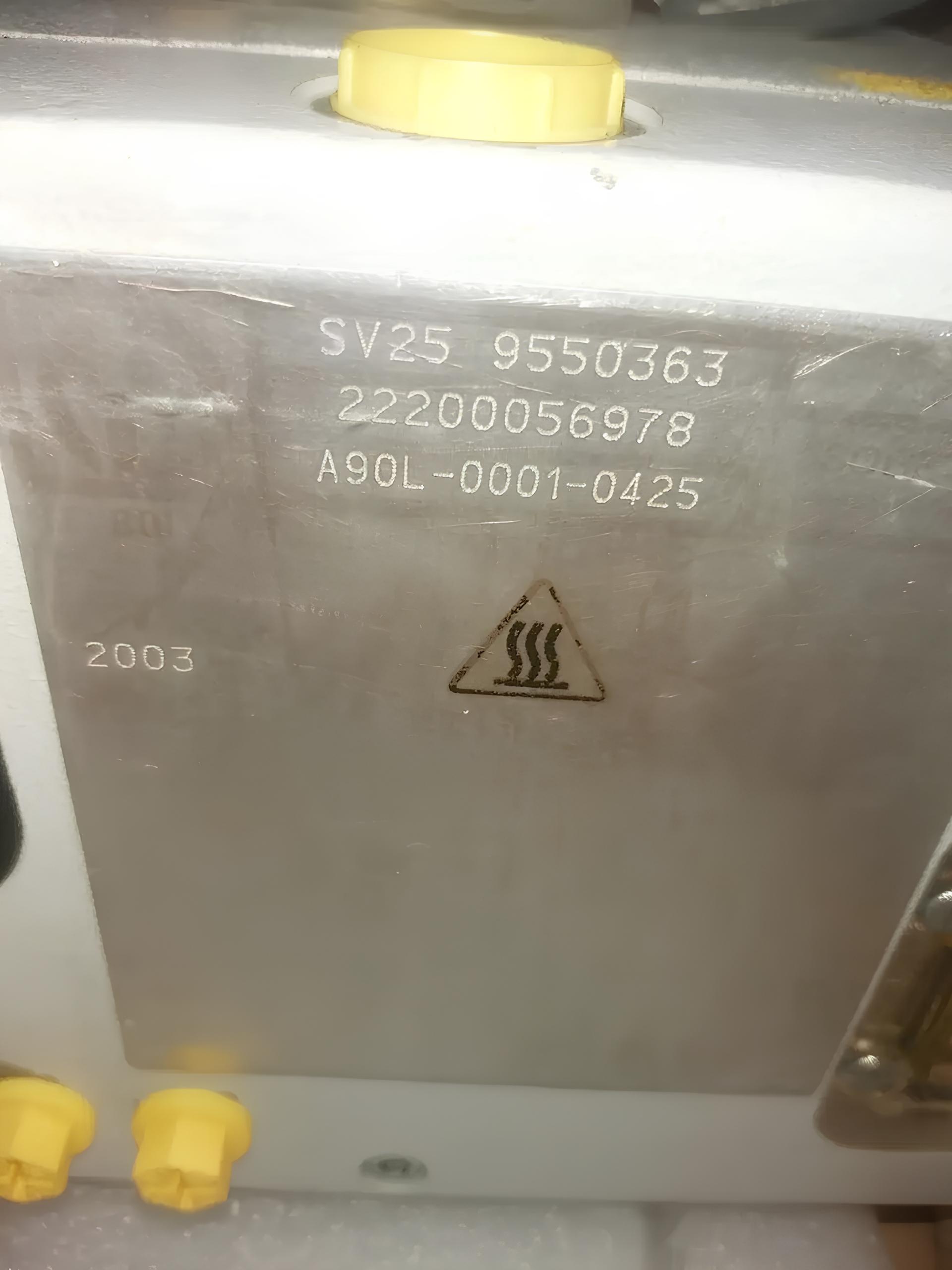

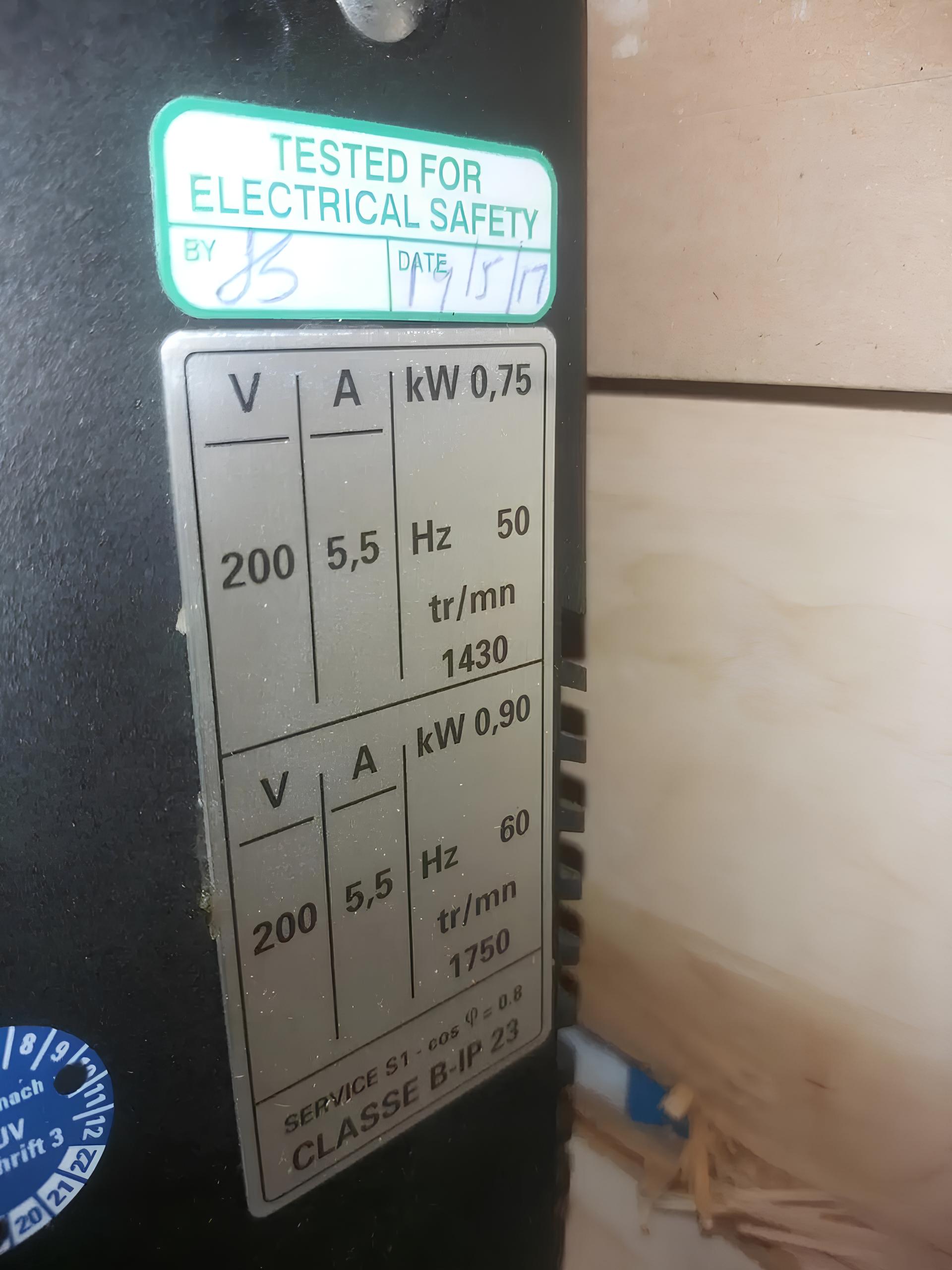

Sogevac SV 16 and SV 25 (A90L-0001-0425) are single-stage, sealed with oil pumps.

Suction valve, gas ballast valve, drain filter and oil return circuit are integrated functional elements Sogevac. The pump is driven by a motor directly integrated with the housing.

The rotor (7/3), mounted by eccentrically in the pump cylinder (7/6), has three flakes (7/4) that share the pump chamber for several compartments. The volume of each of them changes periodically together with the rotation of the rotor.

During the rotation of the rotor, part of the suction pump chamber expands and sucks the gas through the inlet opening (8 / a). The gas passes through a strainer and an open check valve against suction and gets into the pump chamber.

When the rotor is still rotating, the shoulder separates some of the pumping chamber from the inlet.

This part of the pumping chamber shrinks and the gas is compressed, then the gas is excreted from the chamber through the drain valve (7/7-8). Injected oil into the pump chamber is used to seal, lubrication and cooling of the pump.

Injected oil injected by compressed gas is roughly stopped at the bottom of the oil bowl. Then it is carefully filtered in integrated flue gas filtration elements (8/52). In this way, the oil content in the exhaust is reduced below

Visibility threshold (oil recovery coefficient above 99%). The oil remaining in the flue gas filters is recycled to the oil cycle through a non-return valve that prevents its suction. The oil return is controlled by a float valve (8/55).

Oil from the oil tank (8/67) is injected directly and also through the bearing of the end flanges through the openings in these end flanges in the pump. The oil flow is provided by the pressure difference inside the pump.

After opening the gas ballast valve (8/62) to the pump chamber, the measured amount of air - the so-called Gas ballast. This gas ballast prevents the formation of condensate (within the tolerance of the steam given in the technical data) when pumping gases or vapors with condensation properties. Unintentional venting chamber, as well as re-suction of oil when the pump is turned off

Prevents a built-in check valve against suction (8/64).

After switching off the pump chamber pump, it is vented with a gas pump through the pipe in the discharge valve. Because the pressure in the internal portion of the pump is in this case higher than in the suction line, the anti-subsystem valve is closed. The gas supplying into the pump chamber also prevents oil from entering the chamber when the pump does not work. The fan attached to the engine creates an air flow necessary for the cooling of the pump.

Secure payment

Secure payment

Easy going back

Easy going back

Fast delivery

Fast delivery